Cov khoom

SFG Tsis Siv Neeg Solder Paste Tshuab Luam Ntawv A5

Specifications

| Qauv | A5 | ||

| Yam khoom | |||

| Screen Ncej | Qhov Loj | 470 × 370 hli | |

| Max Loj | 737 × 737 hli | ||

| Thickness | 25 ~ 40 hli | ||

| PCB Min Loj | 50 × 50mm | ||

| PCB Max Loj | 400 × 340 hli | ||

| PCB Thickness | 0.4-6 hli | ||

| PCB Warpage | <1% | ||

| Thauj qhov siab | 900 ± 40 hli | ||

| Kev taw qhia kev thauj mus los | Sab laug-txoj cai; Sab xis-sab laug; sab laug-sab laug; sab xis-txoj cai | ||

| Thauj ceev | Max 1500mm / s (Programmable) | ||

| Board qhov chaw | Kev them nyiaj yug System | Magnetic Pin / Up-down rooj | |

Parameter

| PCB qhov chaw | kho / txhawb thaiv | |

| Clamping System | Sab clamping, lub tshuab nqus tsev nozzle | |

| Lub taub hau tshuab luam ntawv | Ob tug ywj siab motorized printhead | |

| Squeegee Ceev | 6 ~ 200mm / sec | |

| Squeegee Siab | 0 ~ 15kg | |

| Squeegee Angel | 60 ° / 55 ° / 45 ° | |

| Squeegee Hom | Stainless hlau (tus qauv), yas | |

| Stencil Sib cais ceev | 0.1 ~ 20mm / sec (Programmable) | |

| Ntxuav System | Qhuav, ntub, nqus tsev (Programmable) | |

| Table Adjustment Ranges | X: ± 10mm; Y: ± 10mm; θ: ± 2 ° | |

| Tshuab | ||

| Rov ua qhov tseeb qhov tseeb | ± 0.01 hli | |

| Kev luam ntawv raug | ± 0.025 hli | |

| Lub Sijhawm Sijhawm | <7s (Tsis suav Luam Ntawv & Tu) | |

| Cov khoom hloov pauv | <5Min | |

| Yuav tsum muaj cua | 4.5-6kg / cm2 | |

| Lub zog nkag | AC: 220 ± 10%, 50 / 60HZ1F3KW | |

| Tswj Txoj Kev | PC tswj | |

| Tshuab Dimensions | 1220 (L) × 1355 (W) × 1500 (H) mm | |

| Tshuab hnyav | Kwv yees: 1000kg | |

Taw qhia

● Scraper system

Arch choj hom ncua kev sib txuas ncaj qha scraper Sau lub taub hau nrog lub programmable thiab ncua kev kho tus kheej stepper lub cev muaj zog tsav.Four log positioning swb hom nrog ob sab sliders ua kom qhov txav tau raug thiab ruaj khov thaum scraper khiav rov qab.Ob txheej ntawm scraper cais Lub taub hau yog tsav los ntawm ob lub siab precision stepper motors, kom ntseeg tau qhov tseeb thiab ruaj khov ntawm lub siab.Lub kaw lub voj kaw lub zog tswj tau raug kuaj xyuas thiab tswj cov squeegee siab thaum lub sijhawm tsim khoom.

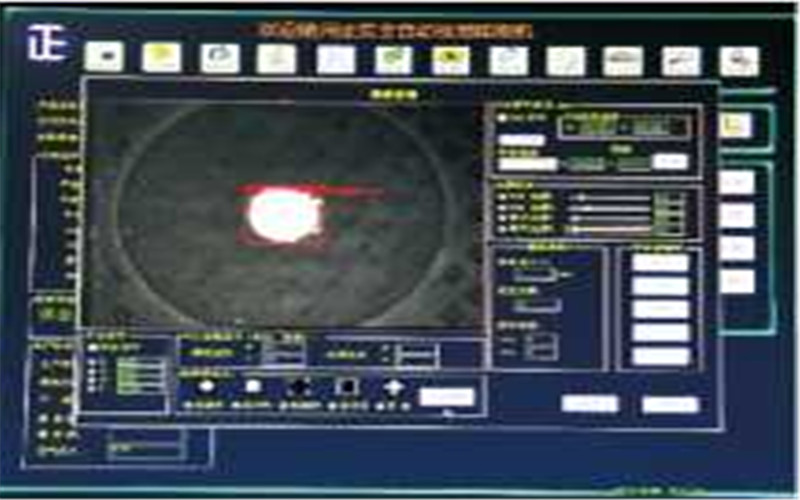

● Duab Thiab Optical System

Uniform nplhaib teeb, siab ci coaxial lub teeb thiab siab siab sab sauv / qis qhov muag pom tag nrho ntawm lub teeb them nyiaj, Tsis siv neeg thiab raug lees paub ntawm txhua hom MARK cov ntsiab lus.Muaj feem xyuam rau tin plating, tooj liab plating, kub plating, tin spraying, FPC thiab lwm yam PCB nrog cov xim sib txawv, muaj peev xwm los xyuas kom meej siab.

● Ntxuav System

Stencil tu system yog tsis siv neeg thiab siv tau.Peb qhov kev xaiv ntawm Kev Ntxuav Qhuav, Ntxuav ntub thiab Nqus Deaning tuaj yeem xaiv los siv, ob leeg ib leeg thiab ntau ntxiv.Thiab koj tuaj yeem xaiv tus thawj tswj hwm manually.Lub tsev rau tus thawj tswj hwm yog sib cais los ntawm CCD lub koob yees duab, uas tuaj yeem txo qhov load ntawm lub cev muaj zog thiab impulse, txhim kho qhov positioning precision thiab ceev thiab txuas ttie kev pab cuam lub neej.Sprinkler systemensures txau tusyees, los ntawm sab saum toj mus rau hauv qab. software muaj nuj nqi tuaj yeem tswj tau cov dej cawv thiab stencil ntxuav daim ntawv, txuag tau ntau dua consumables.Nqus ntxuav yog txaus siab nrog lub siab kiv cua, muaj zog thiab zoo.

● Txoj Cai Tshwj Xeeb Platform Calibration System

Peb axes txuas yog tsim los nrog super-siab dynamic yam ntxwv.lt tuaj yeem kho tus PIN jacking qhov siab ntawm PCB nrog tuab tuab.

● Kev Ua Haujlwm Interface

Siv Windows XP kev ua haujlwm interface, thiab yooj yim rau kev kawm rau cov neeg siv, nrog goodman-machine sib tham sib fu xav.Programi ng yog tsim los nrog kev qhia thiab kev ua haujlwm, kev taw qhia muaj nyob rau hauv txhua kauj ruam.Suav / Lus Askiv xaiv tau ua haujlwm phau ntawv xov xwm / Cov ntaub ntawv sib tsoo / Kev kuaj mob

● 2D Paste Printing Quality Test Thiab Analysis

Xyuas kom meej qhov zoo ntawm cov khoom luam tawm, Qhov no feature tuaj yeem ntes tau sai sai rau kev luam tawm offset, tsis txaus muab tshuaj txhuam, ploj thiab choj thiab ottierdefects.